In the ever-evolving world of construction materials, innovation and sustainability are at the forefront of every builder's mind. One such innovation that is gaining popularity is the chloride-free Mgo board, a remarkable building material with a composition that sets it apart from traditional alternatives.

In this article, we'll delve into the world of chloride-free Mgo board, exploring its composition, applications, and the numerous advantages it offers to construction professionals and homeowners alike.

What is Chloride Free Mgo Board?

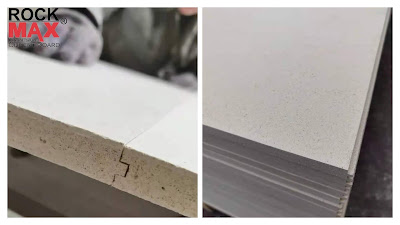

Chloride free Mgo board, also known as Magnesium Oxide board, is an engineered building material that boasts exceptional characteristics while standing out for being entirely chloride-free. Its composition primarily includes magnesium oxide, perlite, and wood fiber. This unique composition provides the board with exceptional strength and fire-resistant properties, making it an ideal choice for a wide range of construction applications.

Applications of Chloride Free Mgo Board

The versatility of chloride free Mgo board is evident in its diverse range of applications:

- Exterior Cladding: Chloride-free Mgo boards are an excellent choice for exterior wall cladding due to their robust and weather-resistant nature, which ensures protection and insulation for the building.

- Interior Wall Panels: Thanks to their fire resistance and soundproofing qualities, these boards are commonly used for interior walls in various settings, including residential homes, commercial buildings, and educational institutions.

- Ceilings: Chloride free Mgo board is often employed for ceilings, offering a smooth and elegant finish to interiors while adding an extra layer of safety due to its fire-resistant properties.

Advantages of Chloride Free Mgo Board

Now, let's explore the key advantages of chloride free Mgo board that are making it increasingly popular in the construction industry:

- Chloride-Free Composition: The absence of chloride in the composition makes these boards safer for the environment and less likely to corrode metal structures, which is a common concern with some traditional construction materials.

- Fire Resistance: Chloride-free Mgo boards are highly fire-resistant, capable of withstanding high temperatures without emitting toxic gases.

- Durability: They are incredibly durable, resistant to rot, mold, and insect damage, ensuring the long-term structural integrity of the building.

- Moisture Resistance: These boards are resistant to moisture, making them suitable for areas with higher humidity levels.

- Easy Installation: Chloride-free Mgo boards are lightweight and easy to handle, reducing labor costs and installation time.

- Versatility: Their versatility allows architects and builders creative freedom in design and construction, while the smooth surface reduces the need for extensive surface preparation.

- Eco-Friendly: The production of chloride-free Mgo boards has a minimal environmental impact, making them a sustainable choice in the construction industry.